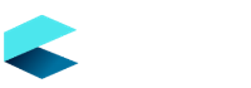

Integrated Flange Management

This scope describe the program, control and specification for the bolt torqueing / tensioning and flange management system. FMS is applicable to piping and equipment nozzle flanged joints which are shown on the isometric drawing with unique flange identification number. FMS scope coverage in piping system are pre-engineering , bolting and assembly completion. The joints for FMS application service will have their own unique tag number managed by joints, and the joints for Non-application service will be managed by packages.

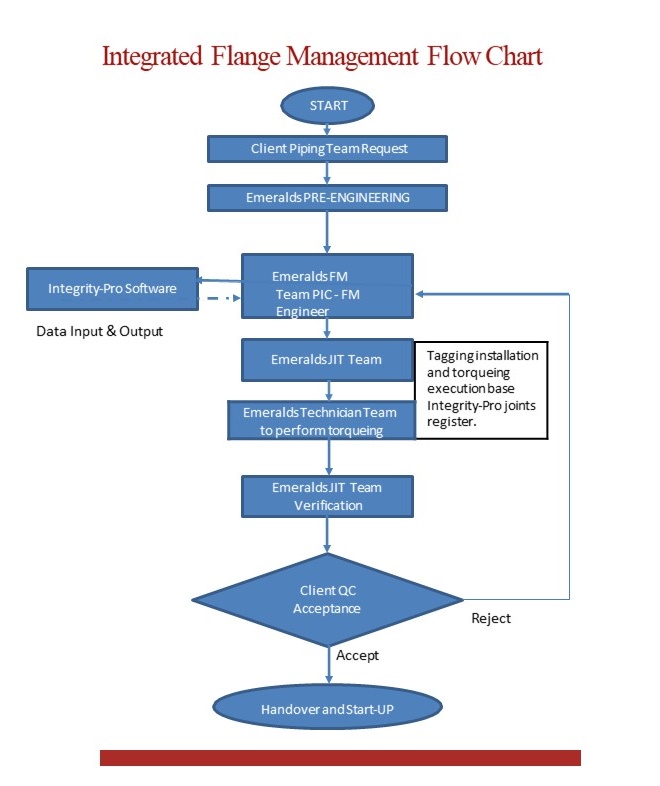

All works on the bolt tightening shall comply with the flange management system software, Data specification is comply with PCC1 2010 and Petronas PTS. We will monitor and execute the process from the pre-engineering to the startup documentation report such as ITRA generated automatic with our advance licensed software Integrity- Pro Flange Management Software. The software capacity can generate 10000 Sheets report with single time.

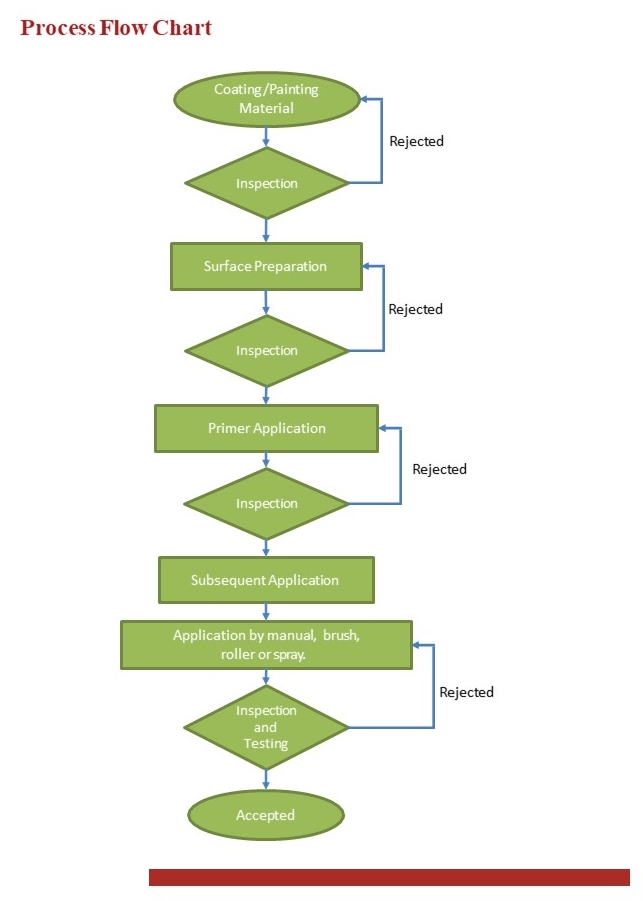

Painting & Coating | Surface Preparation Solutions

Emerald Team provide surface preparation and protective coatings teams work to extremely exacting standards, using the latest technology to deliver advanced solutions to our customers. Our painting and coating solutions are not only

available on site, but can be carried out in a controlled environment at our premises to avoid disruption to your operations.

Surface Preparation

We offer a range of surface preparation solutions with varying work method approaches according to the specialities on site. This ranges from fine blast material such as glass bead for the removal of residues from highly sensitive

equipment, to chilled iron and steel shot used mainly in areas where reclamation and re-use can take place.

Hydro Blasting/UHP Jetting

Our operatives are trained to the highest standards. Before applying protective coatings, standard high pressure water jetting is an excellent solution for the removal of contaminants from almost every industrial surface. Ultra High Pressure (UHP) jetting is an ideal surface preparation method for the removal of substances such as old coatings containing lead. As with all work undertaken in this environmentally sensitive area, we ensure full compliance with the Control of Lead at Work Regulations.

Specialist Coatings

We are able to offer high quality solutions both on and off site, producing the ultimate standards of protection for today’s corrosion requirements. An extensive range of anti-corrosive resistant primers, build up coats and finishes, polyurethane and epoxy resins are available to produce excellent standards of protection for steel and most metal surfaces.

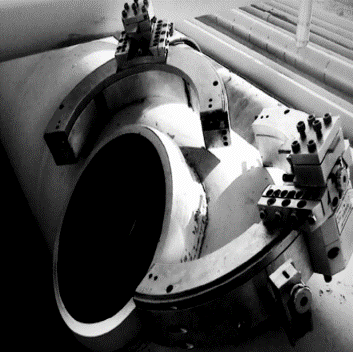

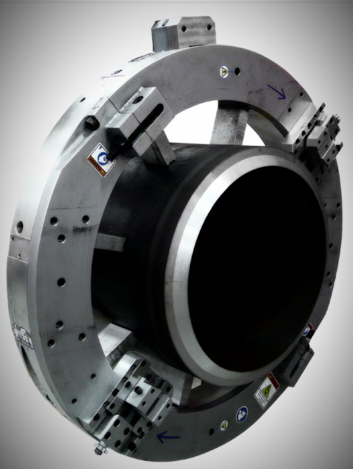

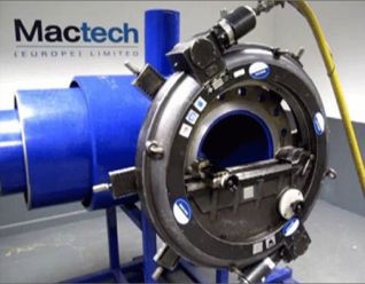

Cold Cutting & Beveling

We have a full range of the equipment for client needs together with highly experienced technicians and technical support team. Most of our experience derived from clients such as Petronas, Shell, Exxon and main contractors. Our cold cutting machines comes in sizes from 2 ” until 24 ” . These machines utilise air motor to operate. The machines is consists of split frame, air motor, cutting holder. Low Clearance Split Frames (known as orbital cutter) are ideal for pipe maintenance and construction work in nuclear and fossil power plants, pipelines, oil platforms, petrochemical plants and refineries, as well as shipbuilding, pharmaceutical, food, beverage and other high purity piping applications.

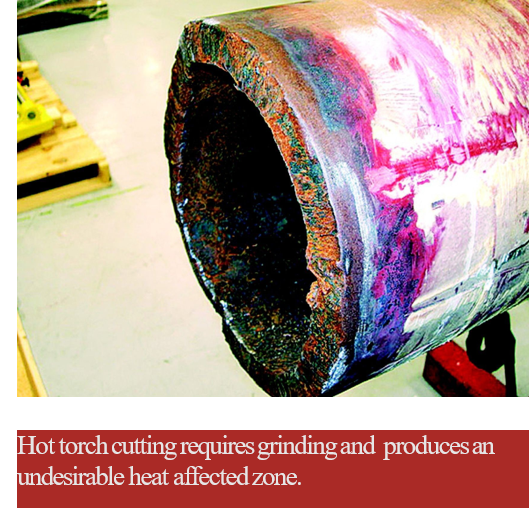

Cold Cutting & Beveling

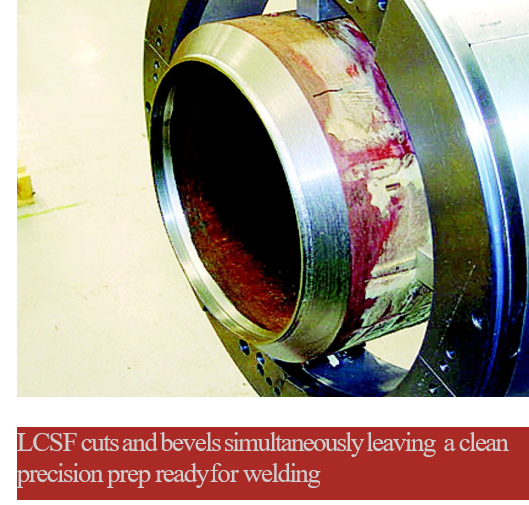

Our LCSF (Low Clearance Split Frame) split frame utilizes a machining cold cutting process, an operation that minimizes the risks associated with hot torch cutting and grinding, particularly important when hydrocarbons are present. Inaddition, torch cutting typically creates a heat affected zone (HAZ) and introduces airborne contaminants into the environment, nacceptable in many worksites and a potential

health hazard.

Bolt Torqueing

We cater to all major sizes and obscure sizes of hydraulic torque wrench ranging from 46 mm – 140mm. Hydraulic torque wrench sets consist of power head, low profile socket, hydraulic hose and hydraulic pump. Minimum radius cassette head for fitment in confined spaces. Our machines provides ccuracy up to +/-3% with standard torque chart supplied. The low profile design for limited access application. Very compact and lightweight equipment.

Bolt Tensioning

Our STS imperial bolt tensioner range is designed for topside operation in a wide variety of applications including pipeline flanges, heat exchangers, pressure vessels, compressor covers, boiler feed pumps, anchor bolts and many others.

The range comprises of 26 imperial size options ranging from 3 ⁄ 4 ”to 4 ” thread size and all models are suitable for working pressures up to 1500 Bar.

Each of the 6 models of hydraulic tensioning cylinder can be operated with a variety of threaded pullers and nut rotating sockets ensuring that the maximum possible range of bolt sizes can be accommodated using the minimum number of hydraulic cylinders.

Hydraulic Bolt Tensioning consists of thread puller, bridge, cylinder, hydraulic hose and hydraulic air pump.

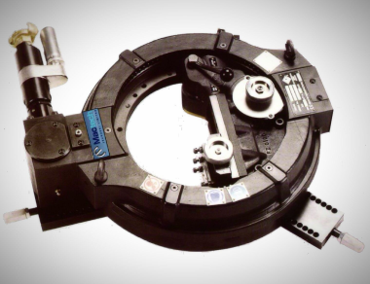

Flange Facing

We cater to all the major and common sizes. Our equipment is compact, lightweight great for onsite machining. Externally mounted which means that its easily mounted. Operates in any position.

Cuts “O ”ring grooves, vertical grooves, “V ”grooves, lens ring seats, hub profiles and weld preparations.

Achieves finishes from 1.6µm Ra to 6.3 µm (63CLA to 250CLA) ‘Gramophoneʼ finish when turning and 0.8µm Ra to 1.6µm (32CLA to 63CLA) when polishing.

Habitat

We have 40 dual power source sets to cater for our clients needs. The power source being pneumatic and electric. Our panels can stand up the heat up to 300 degree celcius.

Our sets stand out from our competitors with the inclusion of Temperature Controller Unit which monitors the temperature within the habitat which will sound the alarm when the inside temperature reaches 40 degree celcius and stop work is initiated.

In addition, our automatic gas detector system comprises of two sensor to monitor Low Explosion Limit (LEL) which is a common feature amongst all current available habitat. Our unique feature is an addditional sensor to detect Hydrogen Sulphide (H2S).

Our units are SIRIM approved and also explosion proof as certified by IECEX and ATEX.

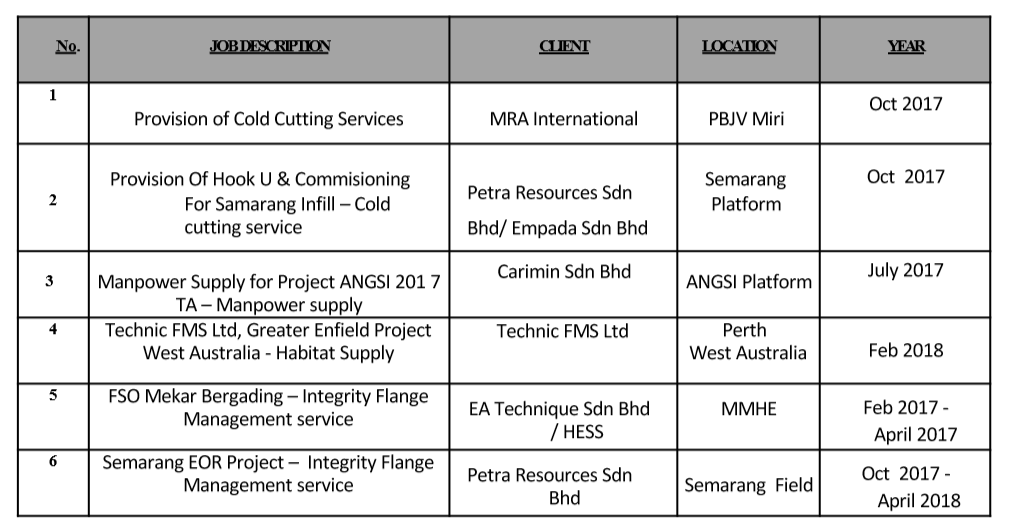

Latest Our Job References 2017-2018